0102030405

Customized Lithium Battery Packs: Precision Manufacturing to Drive the Future

2025-03-17

In today's technology-driven era, customized lithium Battery Packs have become a key solution for meeting the energy needs of diverse devices. From portable electronic devices to electric vehicles and industrial machinery, the demand for high-performance, reliable power supplies continues to grow. Manufacturers of customized lithium battery packs are emerging in this field, providing tailor-made power solutions for a variety of applications.

Customized lithium battery pack production process

(一)Testing of raw materials

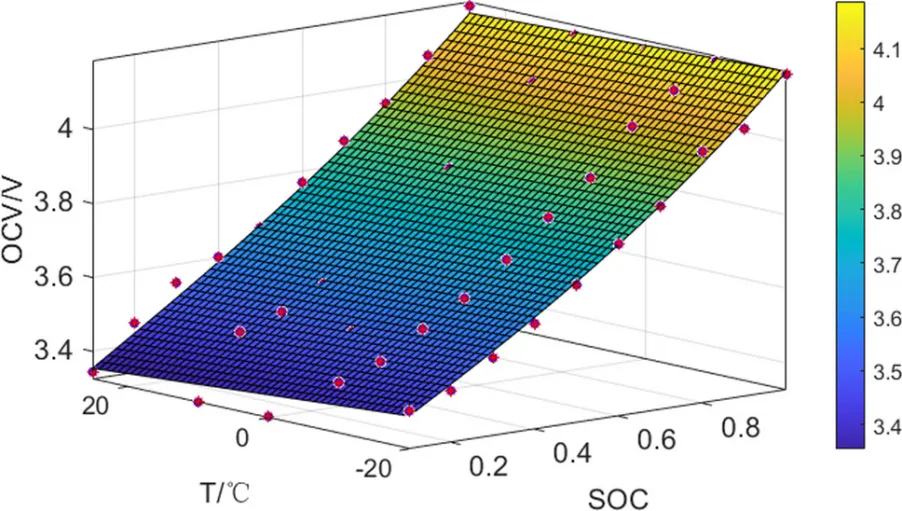

1.of batterySorting cells:Full inspection of the battery cells, the use of automatic sorting equipment, based on the voltage, capacity and internal resistance and other parameters, 18650 or 21700 cells are strictly screened to ensure that the quality of the cells is consistent, which is the basis for ensuring the performance of the battery pack.

2.BMS Testing:Comprehensive Testing Of The Battery Management System (BMS) To Ensure That It Can Effectively Ensure The Safe Operation Of The Battery.

For example: over-charging, over-discharging, over-current, short-circuit, temperature protection and equalization functions.

3.Charger and enclosure testing:All chargers are subjected to 100% quality control testing to verify voltage, current and safety characteristics; battery cases are inspected for appearance, dimensions, structural integrity and material quality, and non-conforming products are returned to the supplier for replacement.

(二)Battery prototype design approval

Prior to mass production, engineers create and test prototypes to ensure that the design meets performance and safety standards. Prototypes are approved before moving to the mass production stage.

(三)Battery Packing

1.Cell pre-treatment and assembly:Incoming material testing is required before the assembly of the battery cell to test the voltage and internal resistance of the battery cell. When assembled, according to the design space, the electric core can be equipped with bracket to enhance insulation, heat dissipation and shock resistance.

2.Automated welding and process checking:Advanced welding equipment is used to ensure a strong connection between the core and the nickel sheet, and the parameters are precisely controlled to minimize defects. During the production process, experienced QC personnel check every hour to ensure the welding quality and nickel sheet pulling force.

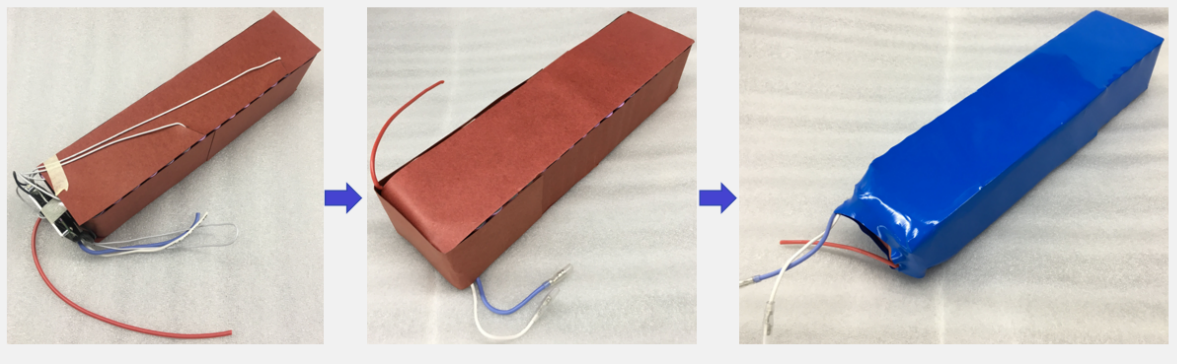

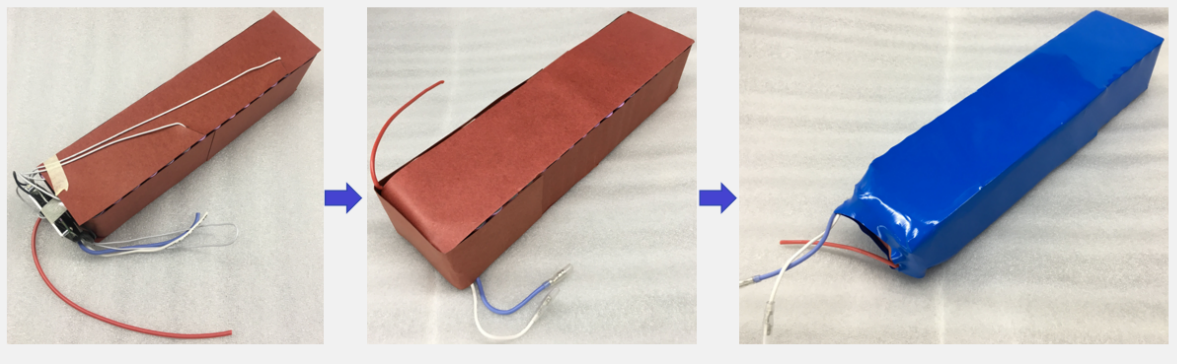

3.BMS installation and semi-finished product testing:After spot welding, the battery pack is assembled, the BMS is welded and fixed, and insulated with PVC heat-shrinkable film. Semi-finished batteries are subjected to a series of tests such as charging and discharging, overcurrent, internal resistance and BMS function.

4.Aging test and shell assembly:Battery packs are subjected to a 100% aging test to simulate actual usage conditions and to ensure that battery performance and cycle life meet customer requirements. If an enclosure is available, after assembling and testing the electrical components, the battery pack is placed into the final enclosure for mechanical reinforcement, electrical insulation and environmental sealing.

5.Finished products are fully tested and packaged:QC staff conducts final inspections of all battery packs, including electrical performance, safety features and appearance, and non-conforming products are returned to the engineering department for analysis. Qualified products are then packaged in customized packaging materials to ensure safe transportation and storage.